RELIABLE TECHNOLOGY. PROVEN EXPERIENCE.

Closed containment – on the farmer’s terms.

What are the advantages of closed containment systems from Fishglobe Technologies?

For fish producers, Fishglobe Technologies is not just a closed containment system – it’s a complete solution built on experience, data, biological insight, and technology that works in practice.

Since 2019, we have produced over 6 million post-smolt in our own facilities. That means we know what it takes to succeed – and we know what matters to you: profitable operations, predictability, good fish welfare, and peace of mind.

• A facility built to make fish production simple.

• The farmer looks after the fish – not the technology. Our expertise is your peace of mind.

• A closed containment system developed for Norwegian conditions.

• Data that delivers insight – not just numbers. Strong bonds between the farmer and the fish.

• More than just sustainability – we aim to create real value

• A scalable system that can be adapted to new sites or changing needs.

• Built by and for fish farmers

• A focus on safety and profitability.

• The most gentle and efficient delivery method on the market. Fish feeding immediately after transfer.

• A control system that gives you full overview – without complexity.

• A solution that halves time at sea and reduces lice exposure.

• The market’s best and simplest integrated sludge collection solution.

• 24/7 operational support and training from people who have raised fish in the globe themselves.

• A delivery that lets you focus on the fish – with support when you need it

This is not about replacing traditional farming – it’s about strengthening it.

With us, you produce strong fish with good growth and lower risk when released into open cages.

That leads to production that is profitable – both for your business and for society.

Technology you can trust – because we had to trust it ourselves

How production is affected with Fishglobe Technologies

Documented quality and reliability

High production volumes with minimal environmental footprint

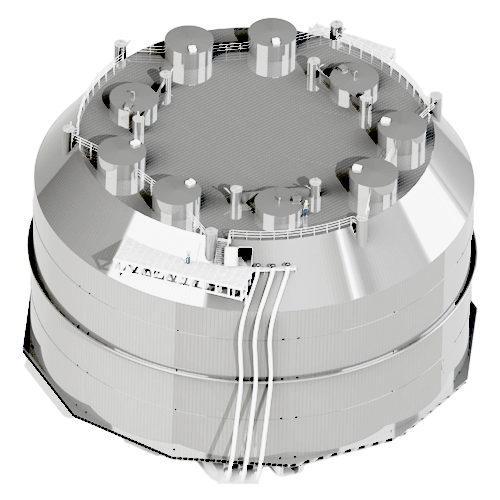

Advantages of our products

Deep-water intake prevents sea lice from reaching the fish, eliminating the need for medical treatment and reducing operational costs.

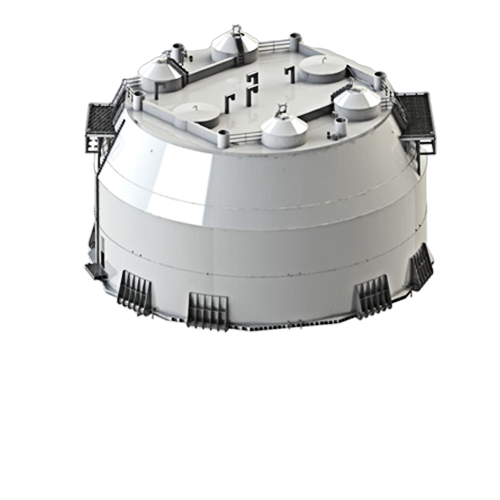

Fishglobe is a fully closed system with double-barrier design, making escapes impossible and ensuring full biomass control.

Precise control of oxygen, temperature and water flow creates ideal conditions for healthy, rapid growth.

Our sludge management system collects sedimentable waste, reducing nutrient emissions and improving environmental impact.

Lower feed waste, reduced mortality and better use of MTB capacity lead to increased profitability.

Fishglobe can be integrated into different production strategies and adapted to both existing and new sites.

Additional key advantages of Closed Containment

• Escapes from aquaculture facilities pose a major threat to wild salmon stocks

• They can lead to genetic dilution and competition for food and habitat

• Fishglobe Technologies completely eliminates this risk and protects wild populations

• Enhances fish welfare and creates better growth conditions

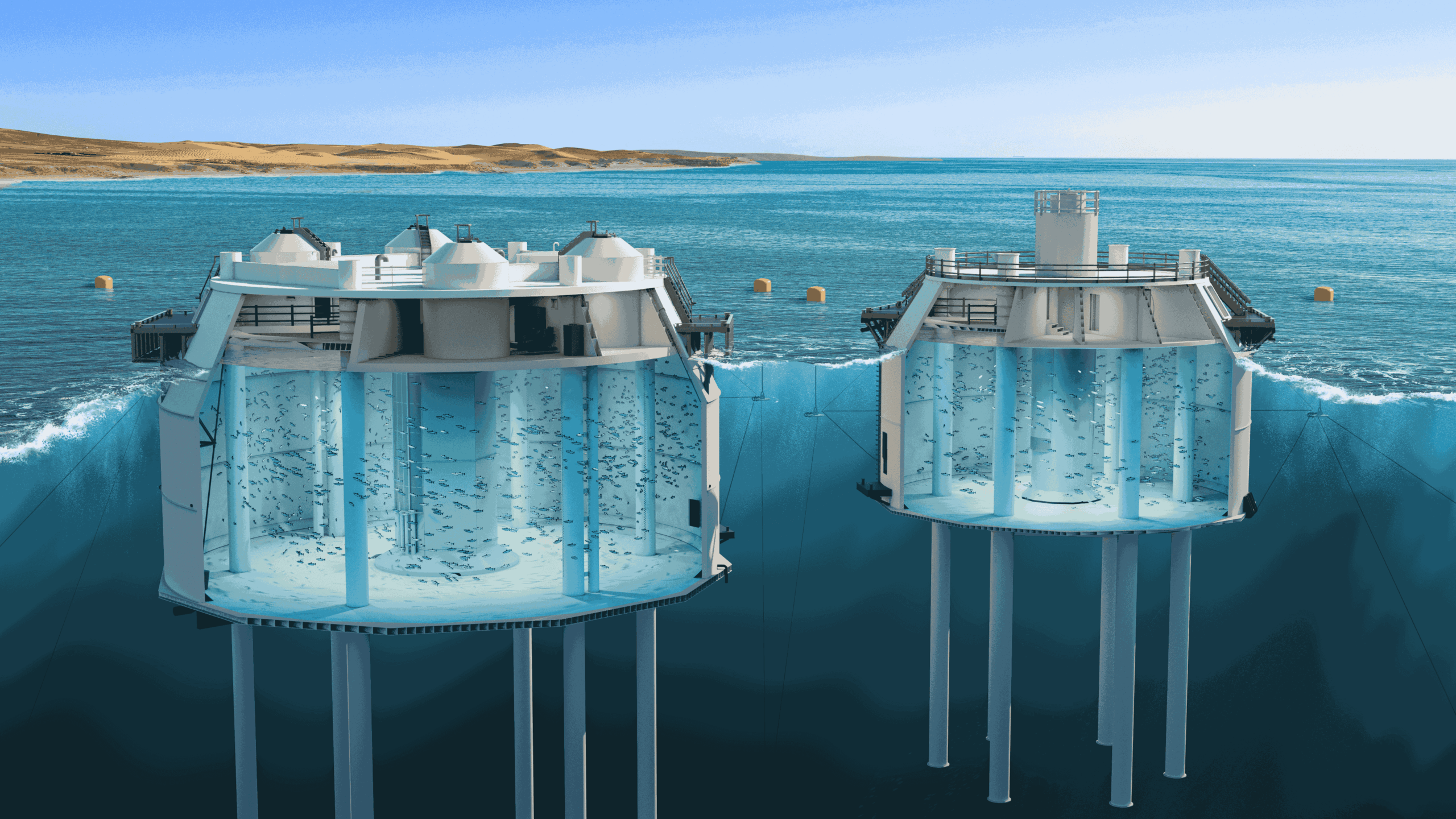

• Deep-water intake ensures access to clean, cold water from below the surface

• Avoids exposure to sea lice larvae and other surface contaminants

• Lower mortality

• Improved fish health

• Reduced need for interventions and treatments

Solving the feeding challenge with SCAF

Ensuring that all fish receive the right amount of feed at the right time is a constant challenge. We’ve solved this with our proprietary SCAF system, which allows for 24/7 feeding while distributing feed evenly throughout the water volume.

We deliver the technology and expertise

to give you full control

The closed containment facility of the future

Full control over the production environment

Ready for the future

So How Does It Work?

Maximising Capacity

An investment in the future of aquaculture

At our local 24/7 centre, Artur and Rodi ensure that we are always there to support the fish farmers.

Scale up – save resources

Fishglobe Technologies improves economic control through predictable production costs.

Our technology-driven approach helps reduce unforeseen expenses and gives customers greater earning potential through improved efficiency and stable production conditions.

Gain full insight into technical and biological parameters and reduce uncertainty.

Identify problems early, prevent equipment failure and avoid production downtime.

Quick troubleshooting, minimal downtime, and immediate assistance with technical issues.

Constant monitoring of oxygen, water quality, temperature and feeding.

Lower risks of escapes, fire hazards, and HSE incidents.

Optimising energy use, feeding and equipment reduces operational costs.

Minimises the need for advanced internal expertise for operating complex systems.